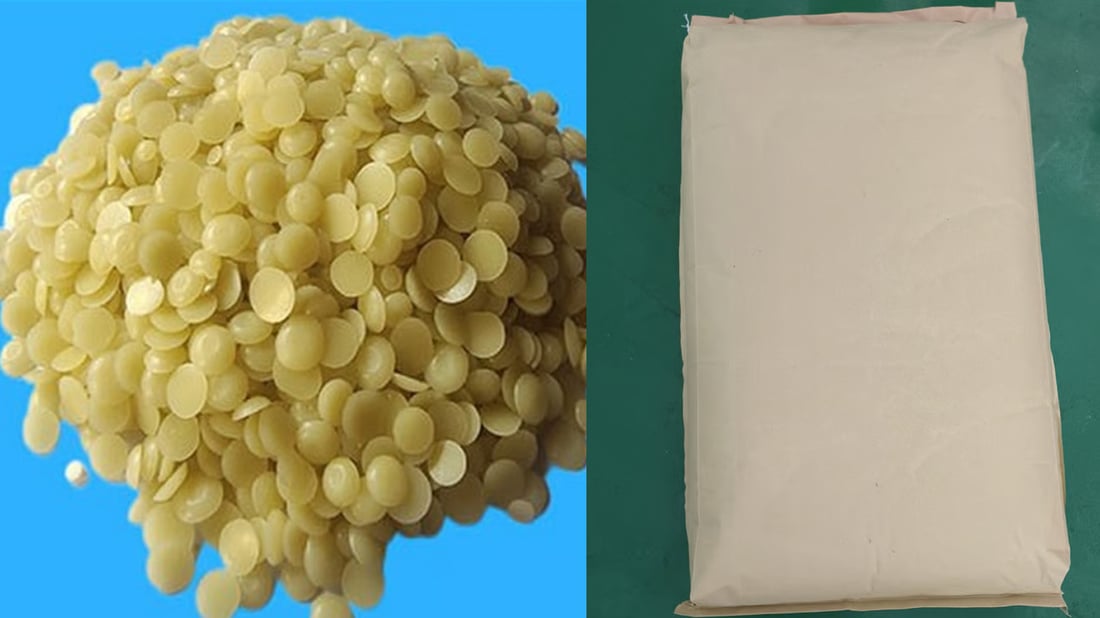

Sumac wax, a natural plant-derived wax, has gained considerable attention for its unique solubility and compatibility attributes. Understanding the solubility and compatibility profile of sumac wax is critical for industries such as cosmetics, pharmaceuticals, and coatings where this wax is used as an ingredient or additive. These properties dictate how well sumac wax interacts with various solvents, oils, and other compounds, affecting formulation stability and performance.

Chemical Composition Influencing Sumac Wax Solubility

The solubility of sumac wax is largely determined by its chemical composition, which typically includes long-chain fatty acids, esters, and hydrocarbons. These non-polar molecules render sumac wax more soluble in non-polar organic solvents such as hexane or chloroform. Its insolubility in polar solvents like water is due to the absence of hydrophilic groups, making sumac wax an ideal candidate for oil-based systems and hydrophobic formulations.

Solvent Selection and Sumac Wax Solubility Behavior

Choosing the correct solvent for dissolving sumac wax hinges on the solvent's polarity and molecular structure. Non-polar solvents, including mineral oils and certain hydrocarbons, promote efficient dispersion and solubilization of sumac wax. Conversely, polar solvents such as ethanol or acetone show limited capacity for dissolving sumac wax, thereby restricting its use in water-based systems unless specialized emulsifiers are introduced.

Temperature Effects on Sumac Wax Solubility

Temperature can significantly enhance the solubility of sumac wax in compatible solvents. Elevated temperatures increase molecular motion, thereby facilitating wax dissolution. This thermal behavior is critical in processes like candle making, cosmetic formulation, or industrial coatings, where heating wax blends are required to achieve homogenous mixtures. However, careful temperature control is necessary to prevent thermal degradation of sumac wax components.

Compatibility of Sumac Wax with Oils and Fats

Sumac wax exhibits excellent compatibility with a variety of natural and synthetic oils and fats due to its hydrophobic nature. This compatibility ensures stable emulsions and blends that are crucial for cosmetic creams, lip balms, and pharmaceutical ointments. Its miscibility with common carrier oils like jojoba, coconut, and mineral oil enhances formulation flexibility and improves product texture.

Interaction of Sumac Wax with Emulsifiers

Compatibility between sumac wax and various emulsifiers affects product stability and performance. Non-ionic surfactants and certain polysorbates show better compatibility with sumac wax, helping to stabilize oil-in-water emulsions where wax particles might otherwise aggregate. Understanding this interplay aids formulators in developing products with superior shelf life and sensory attributes.

Role of Sumac Wax Solubility in Cosmetic Applications

In the cosmetic industry, sumac wax’s solubility and compatibility are exploited to create protective barriers and moisturizers with enhanced texture. Its insolubility in water but solubility in oils makes it an effective occlusive agent that seals moisture. Additionally, when blended properly, sumac wax improves the stability and spreadability of lipsticks, creams, and balms.

Pharmaceutical Formulations Involving Sumac Wax

Sumac wax’s solubility and compatibility traits are pivotal in pharmaceutical topical formulations. The wax is often incorporated into ointments and transdermal patches to provide controlled release of active ingredients. Its compatibility with various medicinal oils and excipients ensures the formulation’s efficacy and patient compliance by enabling smooth application and long-lasting effects.

Industrial Coatings and Adhesives Using Sumac Wax

The use of sumac wax in industrial coatings and adhesives depends heavily on its solubility and compatibility with synthetic polymers and solvents. Its hydrophobicity imparts water resistance and enhances adhesion properties. Proper solvent choices ensure a uniform wax dispersion in coating formulations, resulting in durable, protective layers suitable for packaging and surface treatments.

Environmental and Sustainability Considerations

Sumac wax stands out as an eco-friendly option due to its renewable plant origin and biodegradable nature. Its solubility and compatibility properties allow it to replace petroleum-based waxes in many applications, reducing the environmental footprint. Moreover, its compatibility with bio-based solvents and oils aligns well with green chemistry principles promoted in modern manufacturing.

Quote Inquiry

contact us